Full Digital Twin

Traditional railway bridge inspections usually require direct physical access: scaffolding, utility climbing, restricted rail traffic and high exposure for personnel. In this project, the work area was an active railway bridge, where direct access along the entire length of the superstructure was impossible. However, the objective was clear: to obtain accurate measurements of the structural elements, document the condition of the materials and verify the interaction with the vegetation in the area in a completely non-intrusive manner.

The solution chosen was based exclusively on data: LiDAR and RGB scanning, performed with drones, both for the upper part of the bridge (on top of the bridge) and for the lower part (under bridge), where the support structures partially extend into the water.

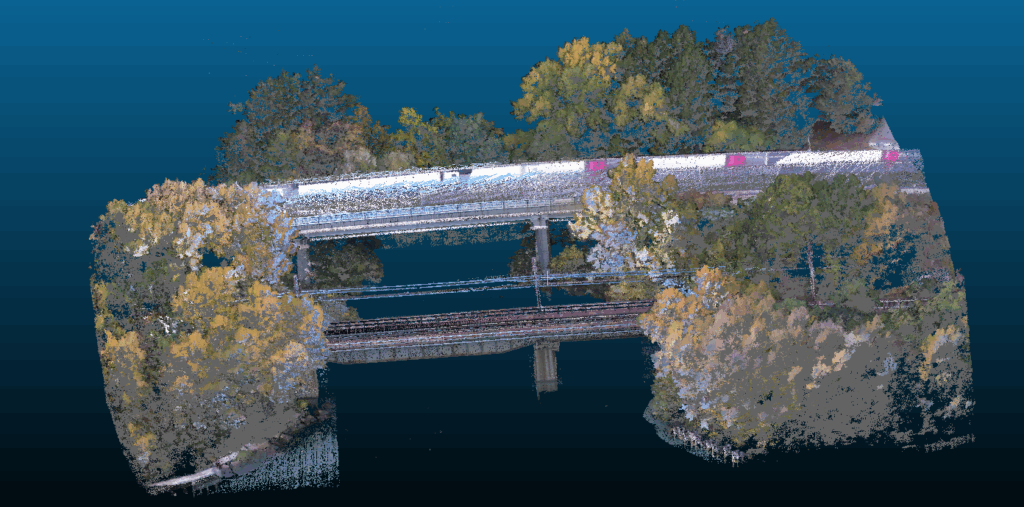

The project aimed to create the first 1:1 Digital Twin of a railway bridge in Romania, combining LiDAR and RGB scanning to provide both accurate geometry and detailed visual documentation of materials and components.

On Top of the Bridge. LiDAR & RGB

Scanning began with the upper structures, where it was essential to obtain the exact geometry of the bridge. The drone equipped with the LiDAR system flew along predetermined trajectories above the bridge, capturing every beam and metal fastener. The flights were planned to cover the entire surface and avoid interference with the active railway network.

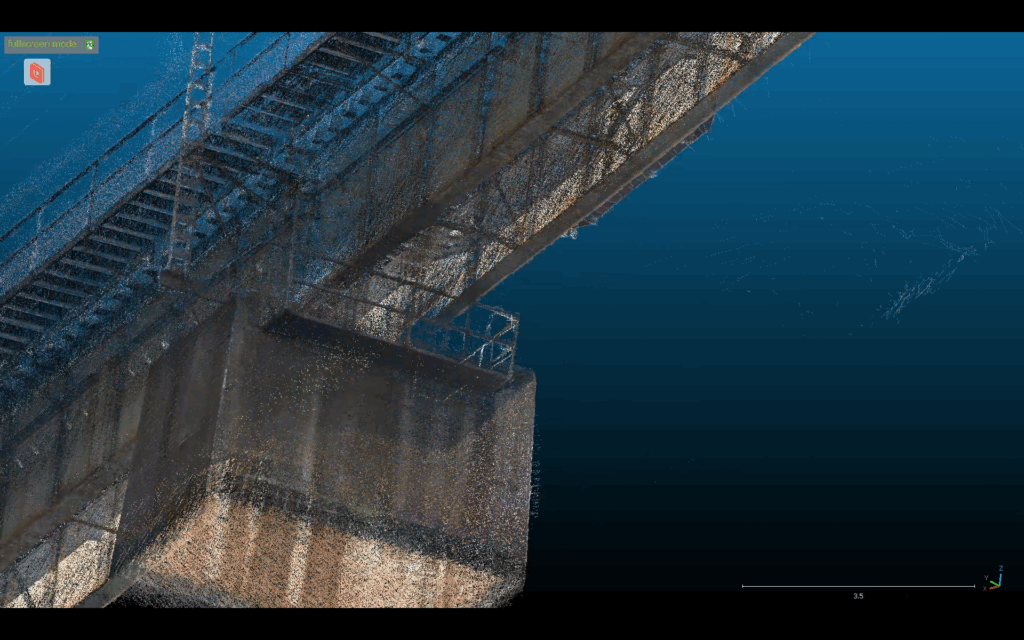

As the sensor collected millions of three-dimensional points, the structure took on a digital form and the resulting model accurately reflected physical reality, with centimeter precision. Each pillar and each beam could be measured and analyzed without physically touching the material.

LiDAR was complemented by RGB, which brought the visual dimension to the analysis: the texture of the metal, areas where the paint had peeled off, the first signs of corrosion or biological deposits. Each photograph was georeferenced and integrated over the point cloud, transforming the 3D model into a Full Digital Twin.

Through this process, the team obtained a measurable 1:1 representation of the upper structure through a faithful three-dimensional map, which allows for the calculation of actual dimensions, analysis of deformations, surrounding vegetation, terrain elevation, and monitoring of the condition over time.

If LiDAR builds the “skeleton,” RGB brings the “skin”: the texture of the metal, areas where the paint has peeled, traces of rust etc.

Thus, visual and dimensional assessment were combined, providing a complete view of the bridge’s condition.

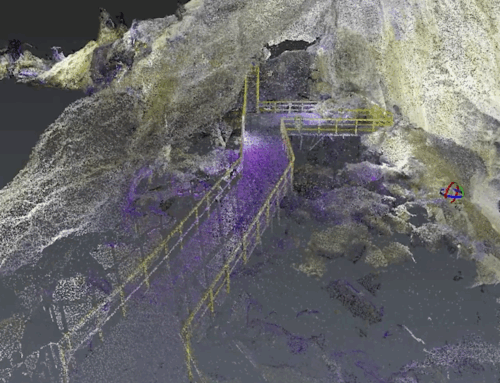

Under Bridge. LiDAR SLAM & RGB

The underside of the bridge presented a distinct challenge. The structure extended over water and the support areas were difficult to access using conventional methods.

For this stage, portable LiDAR technology with SLAM (Simultaneous Localization and Mapping) processing was used, capable of mapping complex spaces. Scanning was performed under the deck, following the contour of the beams and the connection areas with the pillars.

The LiDAR SLAM data was then supplemented with high-resolution RGB images captured from controlled angles to document the condition of the materials in the lower areas. The integration of the two data sets resulted in a complete digital model of the structure under the bridge, in which every detail was measurable and visible.

This “on top & under bridge” combination allowed for a comprehensive, uninterrupted structural analysis, covering both visually exposed elements and those hidden or difficult to observe through direct inspection.

Digital Twin

The final result was a Full Digital Twin of the railway bridge, the first of its kind in Romania. The measurable and textured 3D model integrates:

- the complete geometry of the upper and lower structures,

- visual documentation of materials,

- information about vegetation in the vicinity of the railway,

- the possibility of comparison between subsequent scans.

This model allows engineers to measure any structural element, identify incipient degradation, and assess the dynamics of vegetation that could affect the railway area. More importantly, the entire inspection was carried out without direct access to the bridge, without stopping traffic, and without operational risks.

This approach marks a paradigm shift in the way railway infrastructure is inspected in Romania. For the first time, a complex structure has been documented 100% digitally, using a combination of aerial and terrestrial technologies that offer:

- total non-invasiveness,

- millimeter precision,

- integrated visual analysis,

- the possibility of predictive monitoring over time.

The bridge now exists simultaneously in two forms: one physical, subject to time, and one digital, precise and permanently accessible.

Behind this mission was the Skyline Drones team, which engineered the entire operational flow from flight planning and sensor calibration to digital model integration and validation. Their combined experience in industrial UAV inspections, LiDAR surveying, and photogrammetric analysis made it possible to achieve a level of accuracy rarely seen even at the European level.